What's the deal with decaf?

Decaf coffee used to be considered "lesser" than regular coffee, but its popularity has been rising in recent years and for good reason. The National Coffee Data Trends report from 2017 indicated that those aged between 18 to 24 were the biggest consumers of decaffeinated coffee. In fact, decaf comprised around 19% of all US consumption that year, with demand rising since.

Modern day coffee drinkers are more inclined to gravitate towards great tasting coffee rather than seeking a simple caffeine fix. That's why flavourful Arabica beans have overtaken super-caffeinated Robusta as first choice in cafes throughout the western world. In the past decaf often meant lower quality. But with modern processing methods and starting with high grade, specialty coffee beans, it's possible to find delicious decaf brews that are right on par with their caffeinated counterparts.

What is decaf coffee

Take your regular green (raw) coffee beans, comprising of around 1000 naturally occurring chemicals that make up its unique tastes and aromas, then remove only the caffeine molecules. It's a daunting task that people have been working to improve for more than a century and has resulted in 4 distinctive decaffeination methods that are still used today.

After the caffeine has been separated, coffee beans are roasted and brewed similar to regular coffee. The decaf process inevitably changes the structural integrity of the bean, making it a little more difficult to roast and brew while retaining the inherent flavours and aromas. The green beans come out of the decaf process darker than usual, more sensitive to heat, a little less dense due to the missing caffeine molecules and sometimes lower in moisture content. This requires a roaster with experience and skill, who is dedicated to quality control to achieve a delicious end result.

All decaf processes are highly effective at removing the vast majority of caffeine, though it's never 100%. Worldwide regulations call for a 97% reduction in caffeine, while European standards demand 99.9%.

In Australia, this takes a standard cup of espresso based coffee (such as an 8oz latte) from around 80mg of caffeine down to around 2mg. For comparison, a cup of black tea contains approximately 50mg of caffeine while the equivalent size drink of Coke contains nearly 23mg. Filter coffee and cold brew both have much higher amounts of caffeine due to longer contact time while brewing. A cup of regular cold brew can contain upwards of 200mg per drink!

Why would anyone choose decaf over regular coffee

Health guidelines recommend an upper daily caffeine limit of 400mg. Considering caffeine is present in many other foods and beverages besides coffee, in reality this is about 3-4 cups of coffee per day. Many people find caffeine affects them strongly and can cause anxiety followed by an energy slump, similar to the effects of sugar.

Excess caffeine can exacerbate various health issues. High intakes have been associated with increased risk of cardiovascular disease and high blood pressure. It's also been shown that tannins in caffeine can reduce absorption of nutrients such as calcium, iron and B vitamins. Interestingly, most of the known benefits of drinking coffee are not related to caffeine at all. These include a boost of antioxidants, reduced inflammation, reduced risk of developing type 2 diabetes or gout, and even better liver health. So you can enjoy that cup of decaf knowing you're getting all the good stuff too.

It's important for pregnant or breastfeeding women to reduce their caffeine intake. Most guidelines recommend an upper limit of 200mg of caffeine per day. Exceeding this, particularly in the first trimester, can increase the risk for intrauterine growth restriction and low birth weight. Studies evaluating caffeine intakes less than 200mg per day have shown mixed results. For this reason, many pregnant women choose to forgo caffeine altogether.

Others may want to enjoy a cup of coffee in the evening without staying awake for hours afterwards. Or some may just be sensitive to caffeine while still enjoying the taste of coffee. With all these reasons to avoid it, we think it's pretty important to always have great tasting decaf on offer.

How did decaf come to be

In 1903 German coffee merchant Ludwig Roselius' coffee shipment was accidentally submerged in seawater. He realised most of the caffeine had leeched out but the flavour remained, if a little salty. He experimented with steaming beans with various acids and bases, then removing the caffeine using benzene as a solvent. The successful Roselius Process was used commercially from 1906. Later benzene became known as a carcinogen and this process was discontinued.

Since then other methods have been tried and since found to be toxic, using trichloroethylene (TCE), dichloromethane, and even chloroform. Thankfully there are several modern methods widely used today that are much safer.

The main methods of decaffeinating coffee

The most popular way to remove caffeine from coffee is through the use of solvents, either directly or indirectly. This method accounts for around 70% of decaf today. If a bag of decaf beans doesn't specifically list the process type, it's most likely to be some kind of solvent process. Other more recent methods include water process and CO2 process. Here we'll go into how each of them work.

Indirect Solvent Process

Most commonly used throughout Europe, this is also known as the Conventional Process, Traditional Process or European Process. It uses chemical solvents such as methylene chloride which the Food and Drug Administration has determined any potential health risk is so low “as to be essentially non-existent". Coffee industry practice results in residual levels of methylene chloride close to one part per million, however 10 parts per million is the allowed maximum. Regardless, these chemicals don't survive the roasting process as they vaporise at 40ºC while roasting temperatures generally reach over 200ºC.

How it works:

- Coffee beans are soaked in near boiling water for several hours, until caffeine and other natural chemicals are extracted

- The water is separated and mixed with solvent for 10 hours

- Molecules of the chemical solvent selectively bond with the molecules of caffeine.

- This water is then heated to evaporate the solvent and caffeine

- Beans and liquid are remixed to return the natural flavours and chemicals from the water back to the beans

Direct Solvent Process

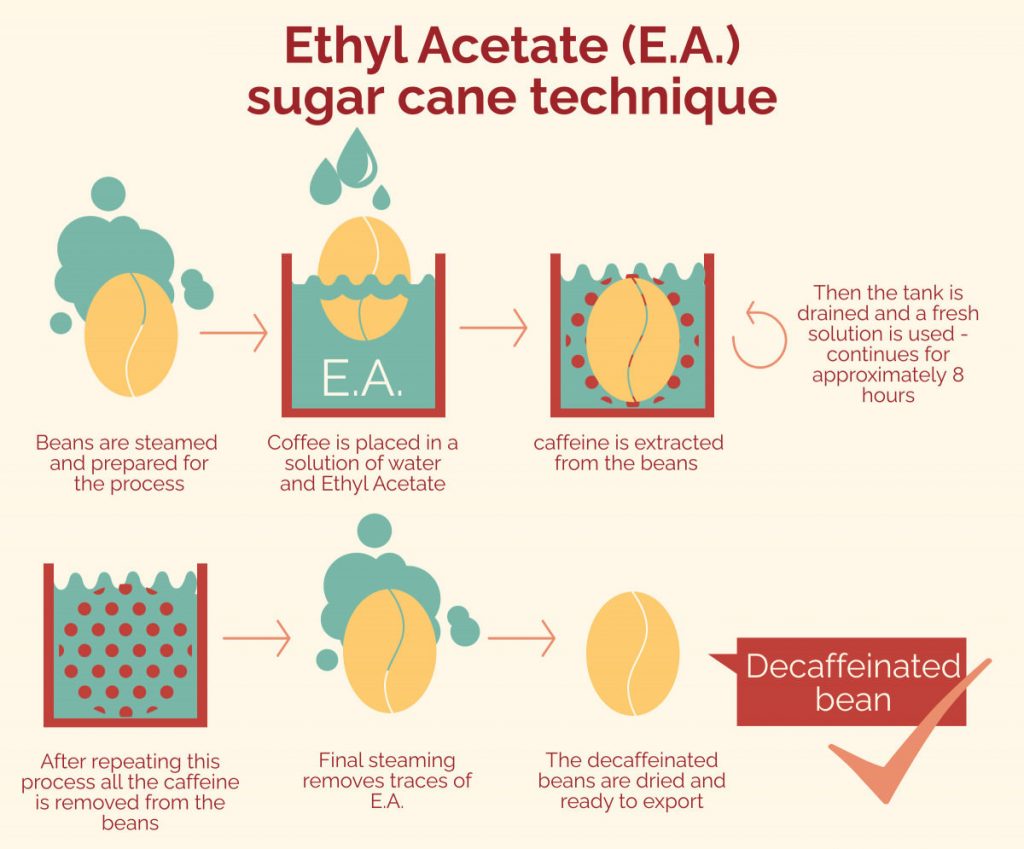

Ethyl Acetate (EA) is the solvent normally used here, which can be derived from natural materials or created synthetically. This method avoids excessive heat or pressure, which can radically disrupt a green bean's cellular structure. One downside of this process is that since the pores of the seed are opened up through steaming, the coffee does tend to age more quickly (both as roasted and green) than regular roasted coffee. You may even see the occasional "sweat" on the roasted bean within several days of roast. In non-decaffeinated coffee, this typically occurs many more days after roast.

How it works:

- Coffee beans are steamed for 30 minutes to open and enlarge cells

- They are then rinsed with EA solvent 10 hours

- The solvent is drained away

- Beans are steamed again to remove any residual solvent

- Finally they are dried to reach the original moisture content

Water Process

Canada's "Swiss Water Process" is what most people have heard of, but there are other patented processes using water around the world such as the "Mountain Water Process" done in Mexico. Swiss Water was developed in Switzerland in 1933 and used commercially since the 1970s exclusively at one facility in Vancouver. It's the only certified organic facility in the world and uses solubility and osmosis to decaffeinate. The resulting coffee is 99.9% caffeine free.

How it works:

- Coffee beans are soaked in very hot water

- Water is then separated and passed through a filter with porosity sized to capture only large caffeine molecules. Smaller oil and flavour molecules pass through

- You're then left with one tank that has beans with caffeine & no flavour, and another tank with caffeine-free flavour charged water

- The flavourless beans are discarded

- The flavour water is then used to remove the caffeine from a fresh batch of coffee beans, infusing them with the previous batch's chemical qualities

CO2 Process

This most recent method was developed by Kurt Zosel, a scientist of the Max Plank Institute. It uses liquid CO2 in place of chemical solvents. The process and materials required is very expensive and typically only used for large volumes of commercial grade, grocery store coffee.

How it works:

- Water-soaked coffee beans are placed in a stainless steel container called the extraction vessel

- Liquid CO2 is forced into the coffee at pressures of 1,000 PSI where it dissolves and draws caffeine from beans

- The CO2/caffeine mix is transferred to the absorption chamber and pressure released

- CO2 returns to a gaseous state and caffeine is left behind

- The CO2 is pumped back into the pressurized chamber for reuse

Sugar Cane Process

This newest decaffeination method is an exciting step in the direction of sustainability. The sugar Cane Process originated in Colombia and is Two Before Ten's decaf method of choice. It uses EA to extract caffeine using the Direct Solvent Process described above. The difference here is that the EA is derived from fermented molasses, a natural by-product of sugar cane processing. Sugar cane growing is abundant in Colombia so it makes sense to combine these two industries to reduce waste and achieve a naturally sweet decaffeination process. In addition to making use of natural by-products and avoiding synthetic chemicals, this method is more sustainable through reduced transport emissions. The sugar cane decaf process is done in Caldas, Colombia, not far from where our coffee beans are grown near Popayan.

The future of decaf

In recent years there has been a move towards utilising coffees that are naturally lower in caffeine. This means skipping the decaffeination process entirely in favour of selectively growing appropriate varieties. One example is the Laurina varietal from Reunion Island. The 2018 World Brewers Cup Champion Emi Fukahori used the Laurina variety in her winning performance, proving that extremely high quality and low-caffeine can exist in unison.

While this is an exciting direction, these "locaf" varieties still contain significantly higher quantities of caffeine when compared to decaf - around 15 to 50% of regular Arabica coffee. They are also more difficult to grow, precisely because of the lower caffeine. It's this chemical within the coffee plants that acts as an immune system for the tree, so selecting for lower amounts means the plant is more susceptible to disease.

Meanwhile, demand for decaf continues to grow in cafes around the world. A report from 2018 showed that 42% of all coffee consumers drink decaf, with young adults leading the trend. It's even being used competitively. Canadian Barista Championship competitor Cole Torode placed third in the World finals using a decaf Gesha variety.

Whatever the reasons are that people are choosing decaf, it's obvious it's here to stay. And with the quality available out there these days there's no excuse not to have a delicious decaf available to customers.